News

How to avoid overload when using round sling?

How to avoid overload when using round sling?When worker use round sling, may overload by unintentionally, it will cause sling crack and tearing, even produce big accidents.

Carl Stahl analysis the reason of hundreds of round sling cracks in 2019-2020 year, we found that the overload causes a large proportion of sling crack.

Many customers feedback that they have realized this importance, but they don’t know how to prevent overload in the process of selection and use.

- When choosing the standard of round sling, it is necessary to consider the standard, weight, shape, angle and lifting method of the load to be lifted.

- Please read the label and instruction of round sling carefully.

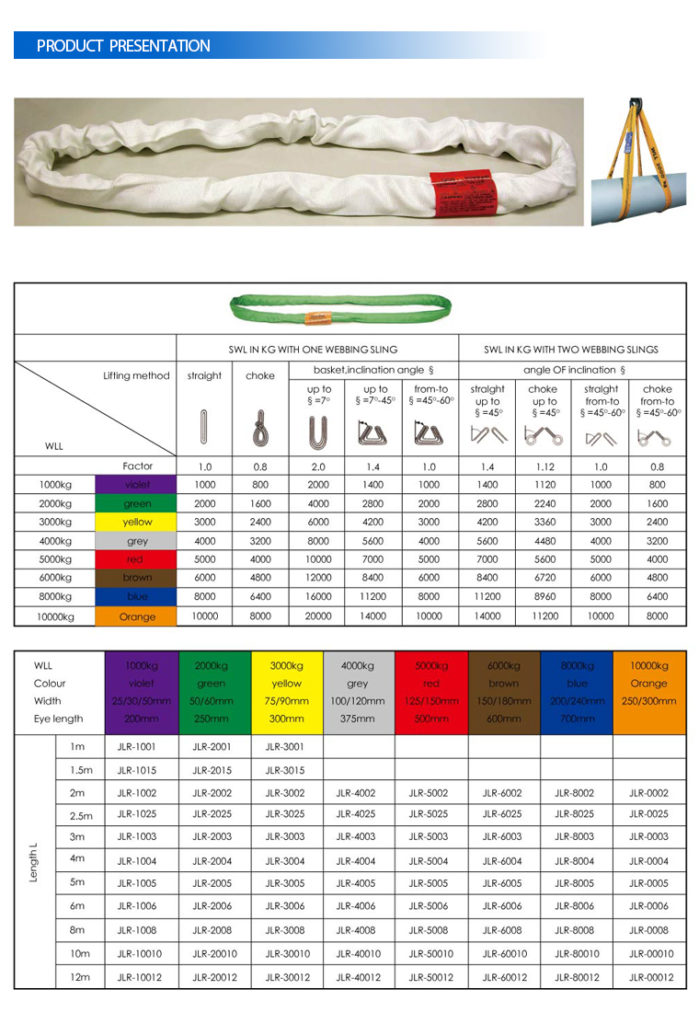

It indicates the WLL, color of round sling, angle and SWL in kg with one webbing sling or two webbing sling.

3.If several flexible round slings are used together, it is necessary to select the same ton and length of round sling.

4.Whether the attachment or soft lifting lug is necessary, it is necessary to reinforce the end of the sling and assist the attachment, such as the hooks, eye bolt, shackle and so on.

5.The experienced worker train the new worker before using the round sling, or ask the lifting professor how to use round sling.

6.You should inspect the round sling regularly, if cracks please don’t use it.

7.Do not pull from under the load or allow the load to rotate on the round sling.

Carl Stahl GMBH supply EN 1492-2, safety factor 7:1 standard round sling and offer professional lifting method for your selection.